Meat processing solutions from Kortlever Industries

Kortlever continuously develops innovative production processes for new or existing meat products, using today’s technical possibilities.

Further processing solutions from Kortlever

Kortlever continuously develops innovative production processes for new or existing meat products, using today’s technical possibilities.

Cordon bleu

We offer two different production processes: the sandwich-method and the folded-method.

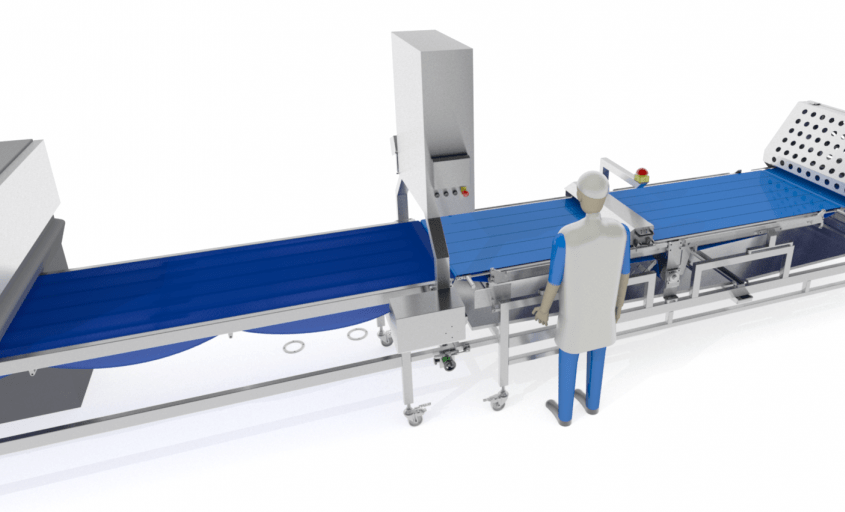

The sandwich-method

The patties are supplied in right shape. The filling is supplied on row 1-3-5 etc. e.g. ham and cheese (by means of a slicer) or a liquid mix of it (by means of a dosing unit).

Afterwards, row 1 is put on a resting conveyor by means of a panning machine. Row 2 is put on top of row 1, etc. With a special sealing device, row 1 and 2 are patted down and transported to a battering installation and a frying line.

Available in 4- and 6-row execution.

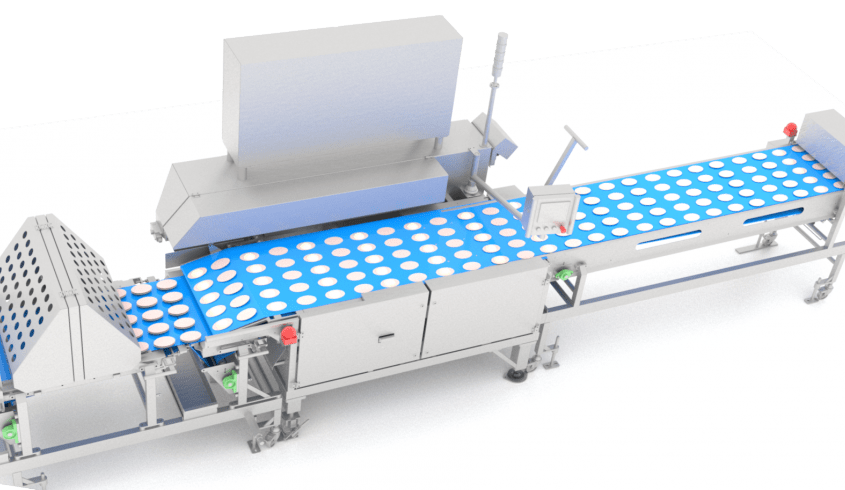

The folded method

The patties are supplied in right shape. The patties are supplied in right shape. The filling is supplied on every patty, e.g. ham and cheese (by means of a slicer) or a liquid mix of it (by means of a dosing unit).

The patties are folded with a folding machine so that a halfmoon shaped cordon bleu is made. With a special sealing device, the patty is patted down and transported to a battering installation and a frying line.

Available in 4-, 6- and 8-row execution.

Bacon wrapped sausages

This traditional meat product is made out of:

- bacon with therein:

- seasoned minced meat filling

There are two different forms of appearances:

a) A completely closed bacon wrapped sausage with sealed sides

b) A bacon wrapped sausage with open sides.

The usual weight of a bacon wrapped sausage is 100 gram and 40 gram of the mini version of it.

For the production of closed bacon wrapped sausages, two bellies are formed to a so-called T-shape (compressing and tempering).

A bacon wrapped sausage line works on 5 product rows.

- 5 T-shaped slices are put next to each other by means of a slicer.

- Minced meat is portioned on the T-shaped bacon slices.

- Afterwards, the side pieces are folded up and rolled up.

The bacon wrapped sausage with open sides is rolled up in a single way.

Contact information

- Energieweg 33 & 10

- 4231 DJ Meerkerk

- The Netherlands

- +31183352955

- info@kortlever.nl

- service@kortlever.nl

Welkom bij