Bread processing solutions by Kortlever

Kortlever specializes in bread processing and has a range of dough conditioning and handling systems, dough processing lines, product handling installations, end of line logistics installation and intralogistics solutions. Kortlever can also be used for projects & customized solutions.

Dough conditioning and handling systems

Kortlever offers a wide programme for dough proofing and conditioning, products for bulk dough and dough pieces. From longterm fermentation to inline fermentation and weight control for precies product portioning. Including airconditioning and housing.

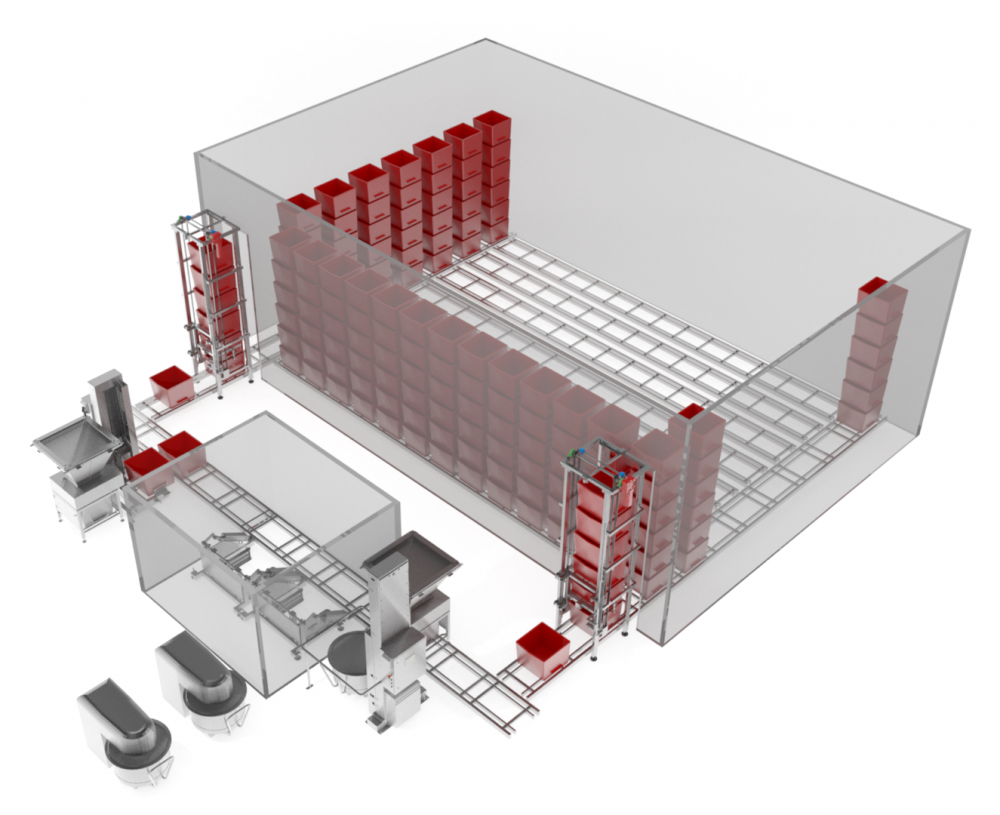

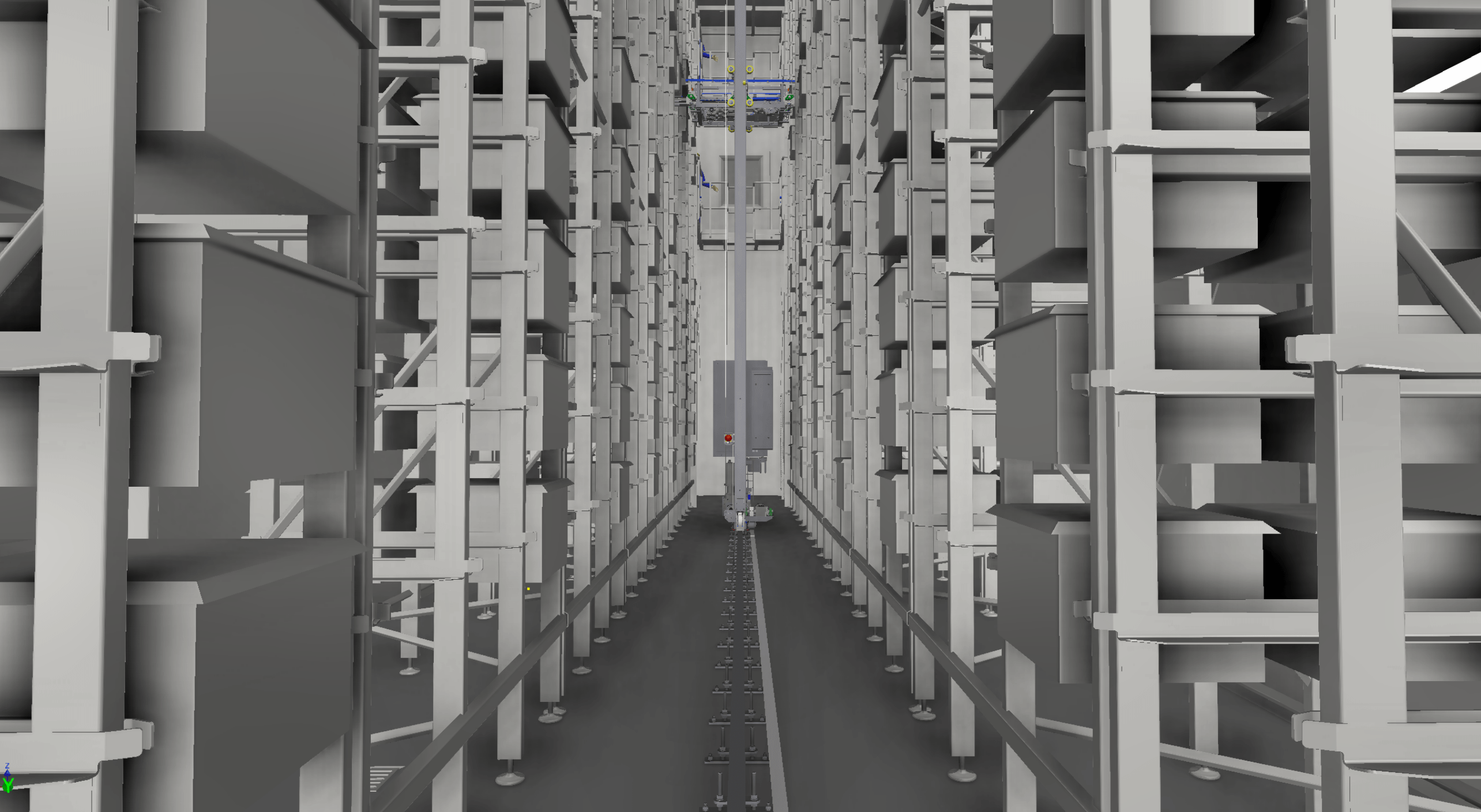

Long fermentation system

- Including portioner

- Crate & box handling

- Linear

- Mini-load

- Automatic conditioning

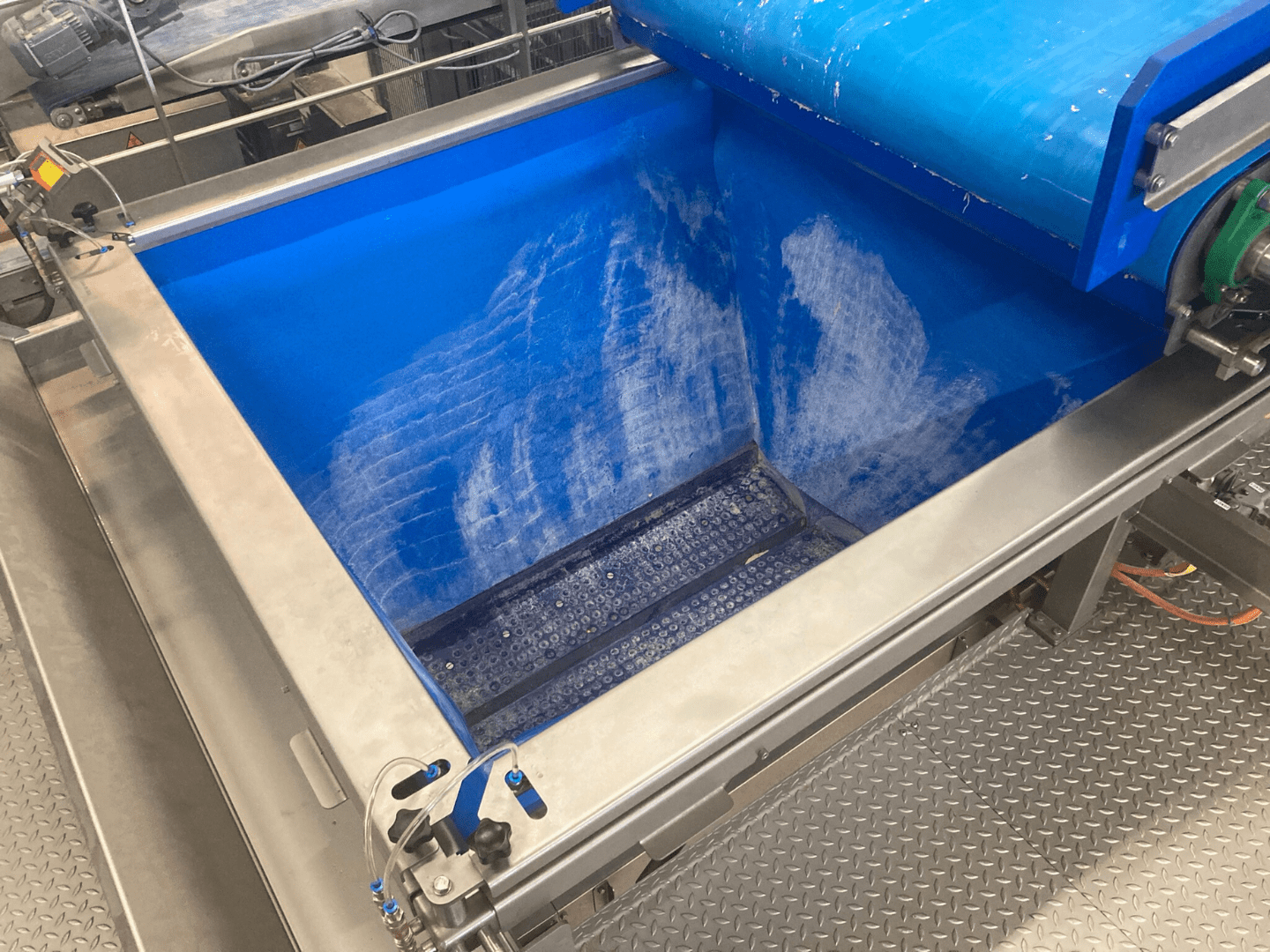

Option: washing system

Capacity: 500 up till 4.000 kg/hr

Fermentation time up to 24 hours.

This is the production process for authentic / high quality breads.

Inline dough sheet proofers

Application:

- Linear and industrial high capacity production of raised dough products made of a laminated dough sheet.

- Cooling of puff paste and croissant dough sheet to a constant temperature.

- The rising of individual dough pieces.

Automatic inline conditioning of dough, based on temperature, humidity and time.

Up to 120 minutes. Temperature range: +10 to +35ºC Dough sheet width up to 1.500 mm.

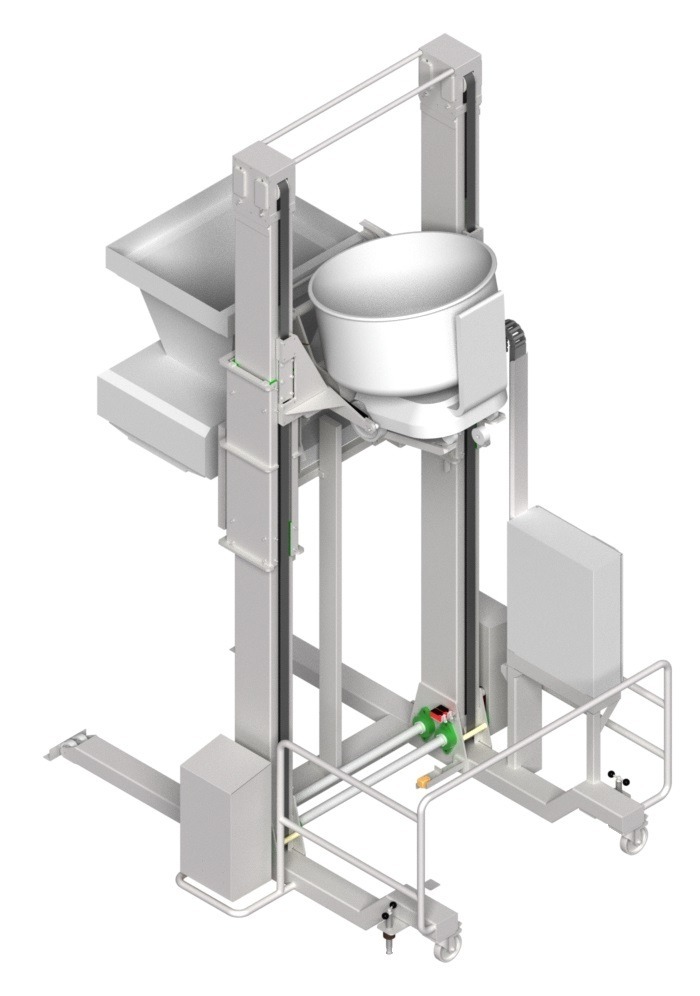

Bowl elevators

Lifting motion by means of a plastic geared belt. Provided with a mechanical fall protection. Lifting load up to 600 kg. Available for all known dough bowls.

Optionally provided with:

- Bowl rotation

- Bowl scraper

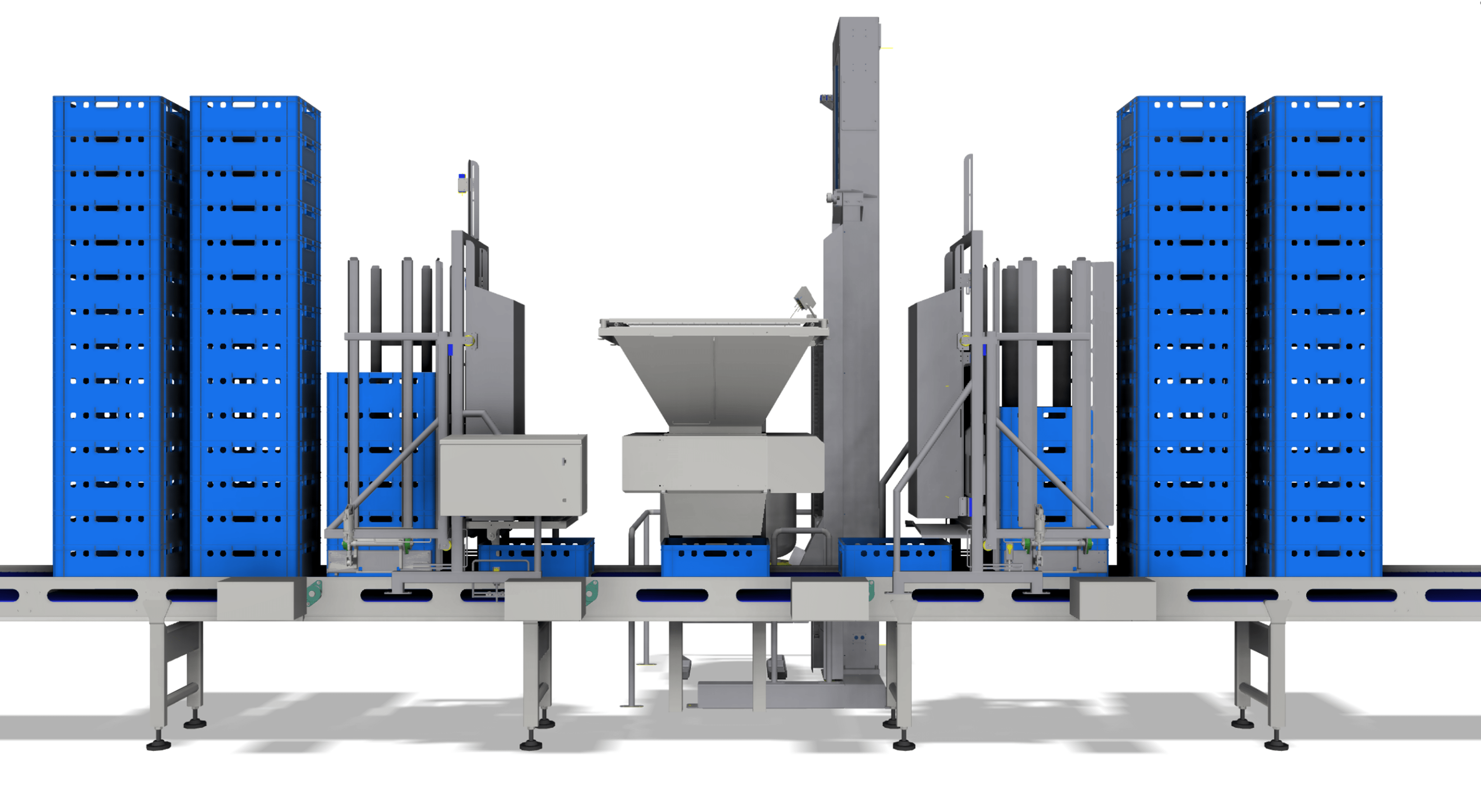

Star-portioner

For portioning of dough into pieces from 10 to 50 kg.

Application:

- Feeding of bun and sheeting lines

- Portioning for long fermentation processes

Available in combination with a bowl elevator.

Contact information

- Energieweg 33 & 10

- 4231 DJ Meerkerk

- The Netherlands

- +31183352955

- info@kortlever.nl

- service@kortlever.nl

Welkom bij