Meat processing solutions from Kortlever Industries

Kortlever continuously develops innovative production processes for new or existing meat products, using today’s technical possibilities.

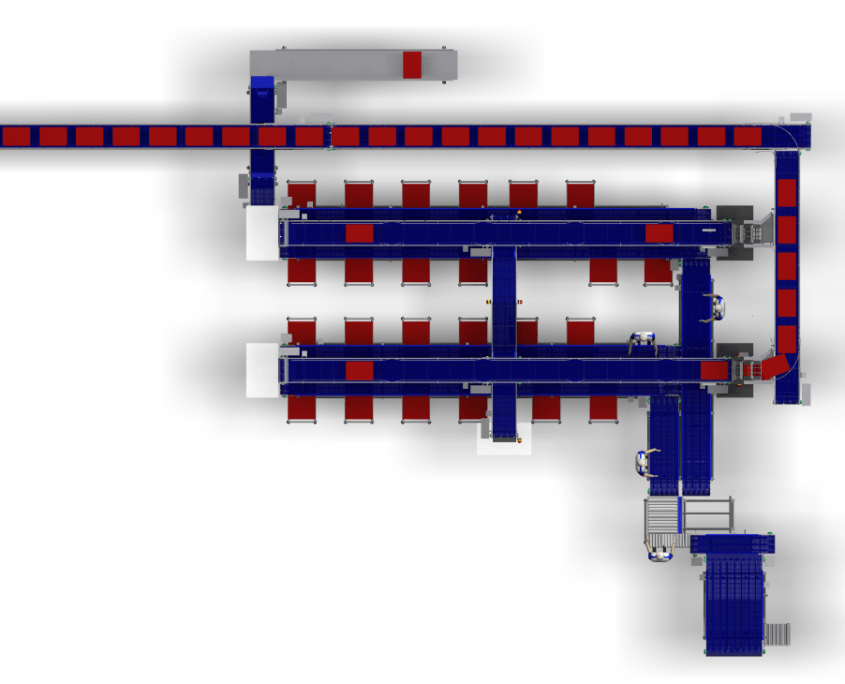

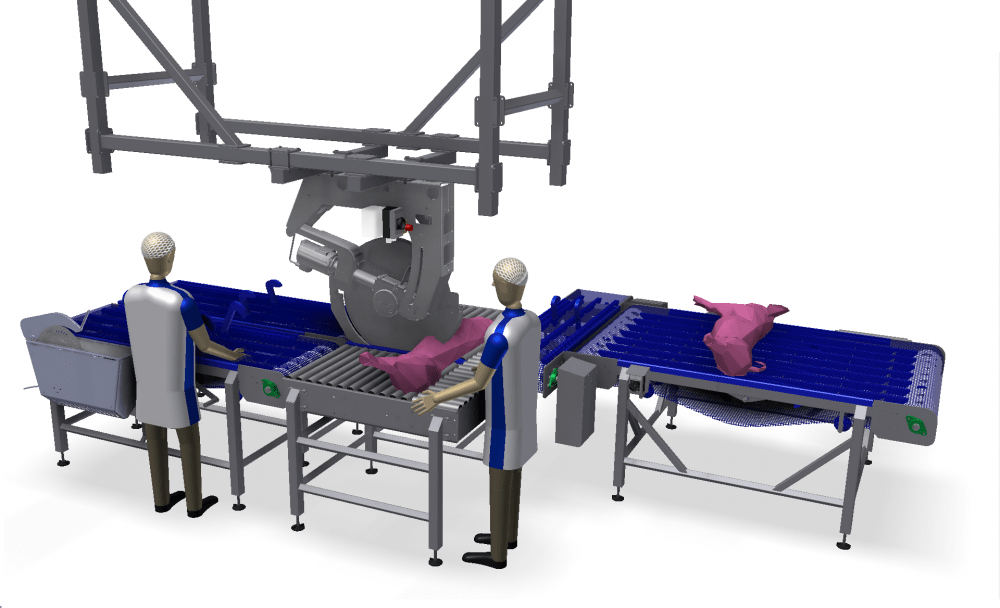

Kortlever designs and manufactures customized deboning solutions for dividing of pork and beef carcasses. Our ergonomic layouts comply with applicable health and safety regulations.

The pork carcasses are automatically supplied from the cooling area, put on a deboning conveyor and, afterwards, are divided in leg, loin/belly and shoulder by means of a laser controlled cutter. The same procedure can be applied on beef deboning as well.

After dividing, the technical parts are automatically carried with various deboning belts to workstations for further processing and transport.

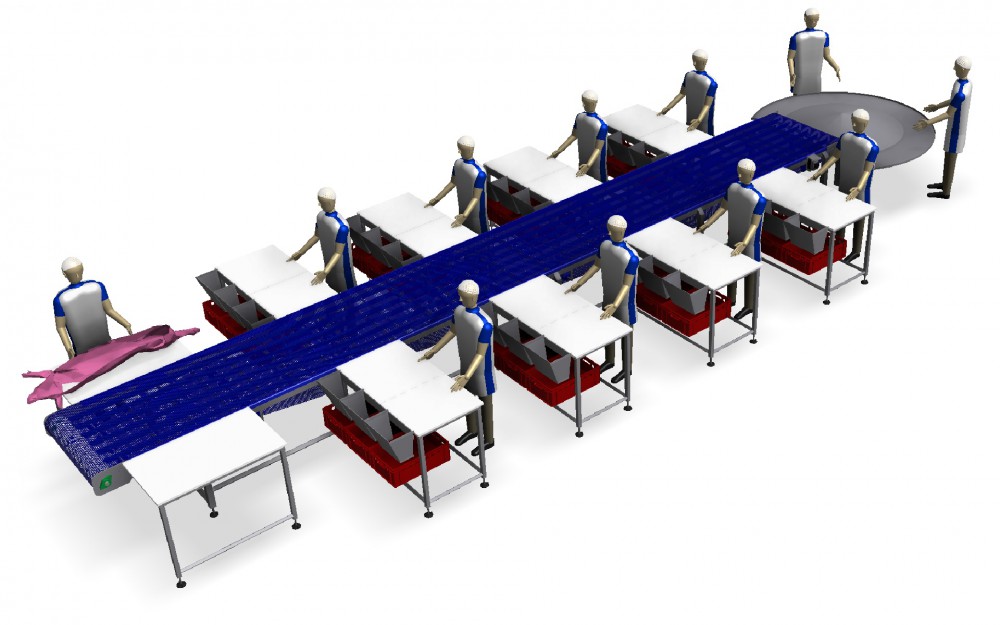

Table deboning

Table deboning enables butchers to execute their work at tables. The butchers make multipe “cuts”.

The conveyor belts used are:

- Ergonomic

- Hygenic and easy to clean

- Solid

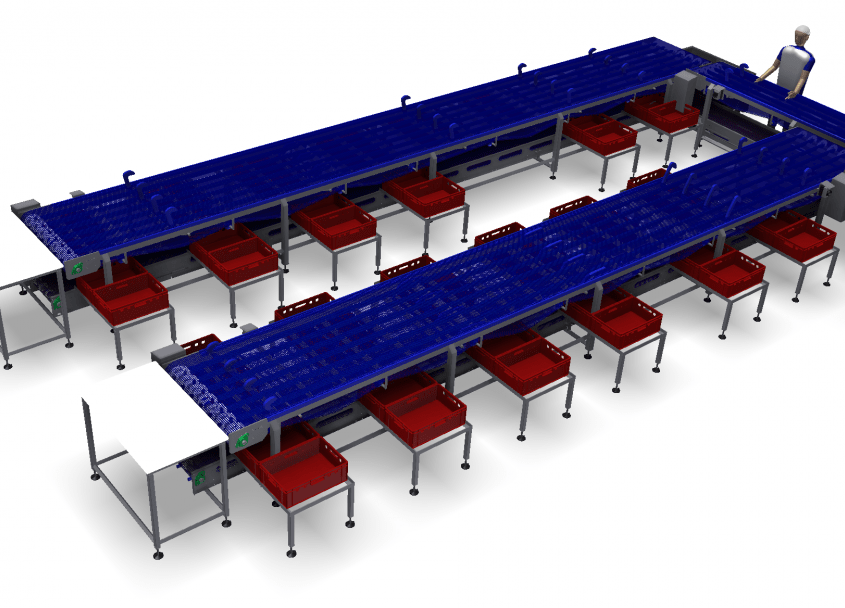

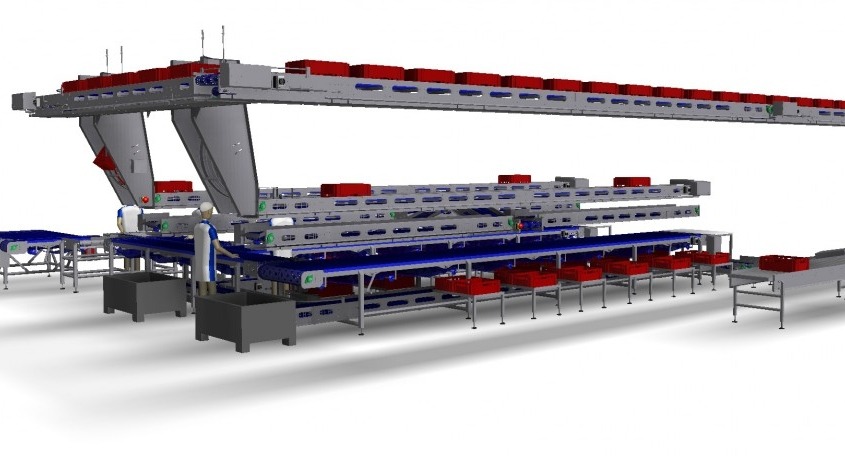

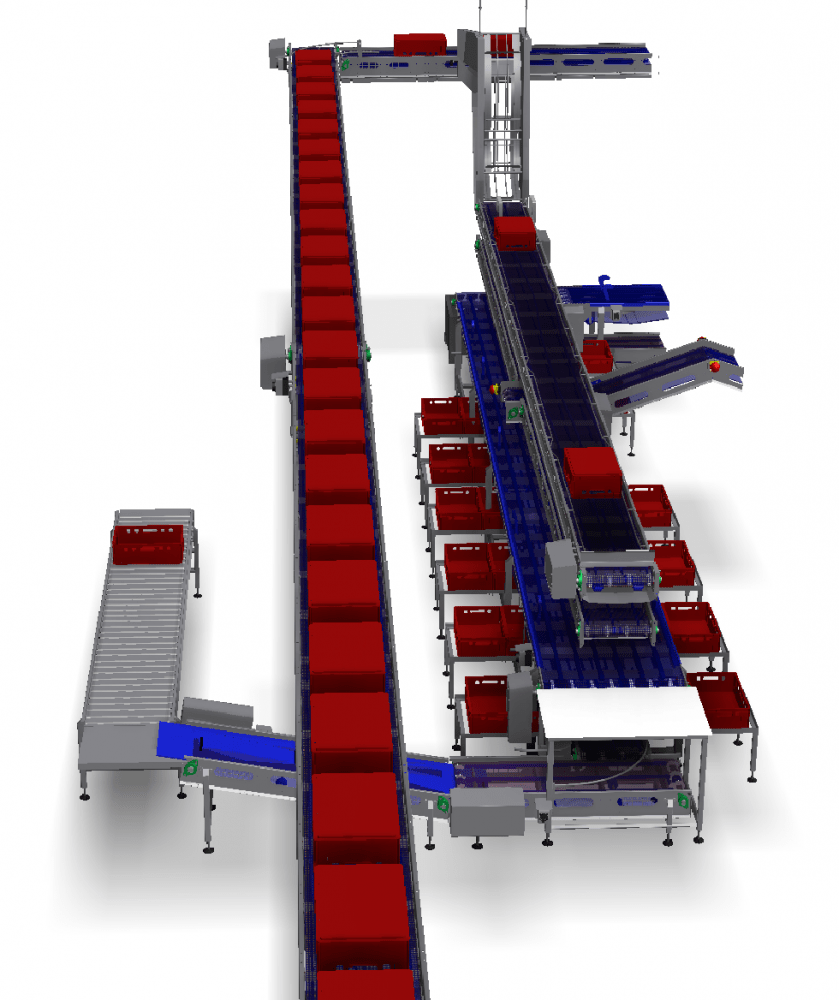

Pace deboning

Pace deboning enables butchers to execute their work at the conveyor belt which carries the carcasses through the deboning area. The conveyor belts suit as work station in order to further debone the parts of the carcasses. Every butcher has his/her own task within the deboning process. The speed is set by the conveyor belt.

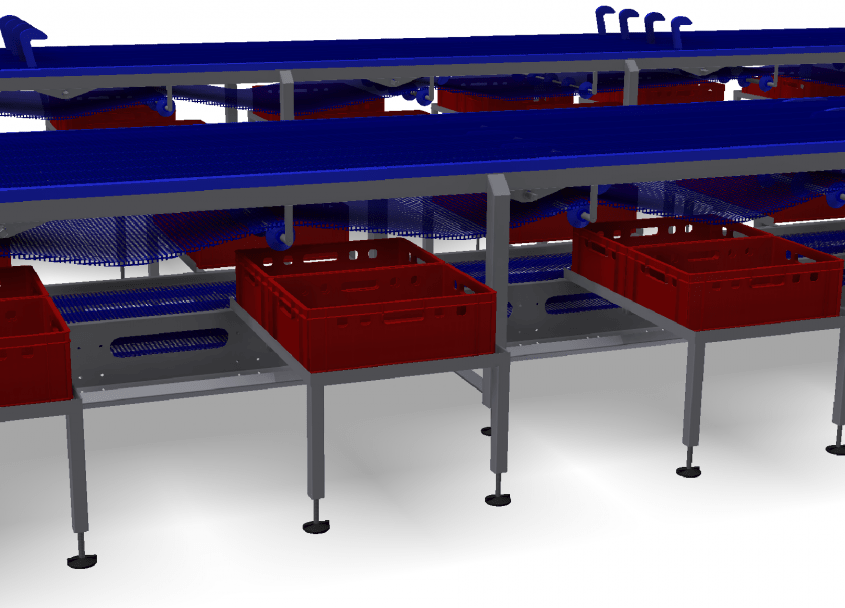

The conveyor belts used are:

- Ergonomic

- Hygenic and easy to clean

- Solid

- Suitable for adding optional belt lifters

- Suitable for adding optional CIP (Cleaning In Place)

- Suitable for adding optional catch plates

Contact information

- Energieweg 33 & 10

- 4231 DJ Meerkerk

- The Netherlands

- +31183352955

- info@kortlever.nl

- service@kortlever.nl

Welkom bij