Bread processing solutions by Kortlever

Kortlever specializes in bread processing and has a range of dough conditioning and handling systems, dough processing lines, product handling installations, end of line logistics installation and intralogistics solutions. Kortlever can also be used for projects & customized solutions.

Producthandling solutions from Kortlever

Product handling installations for dough products.

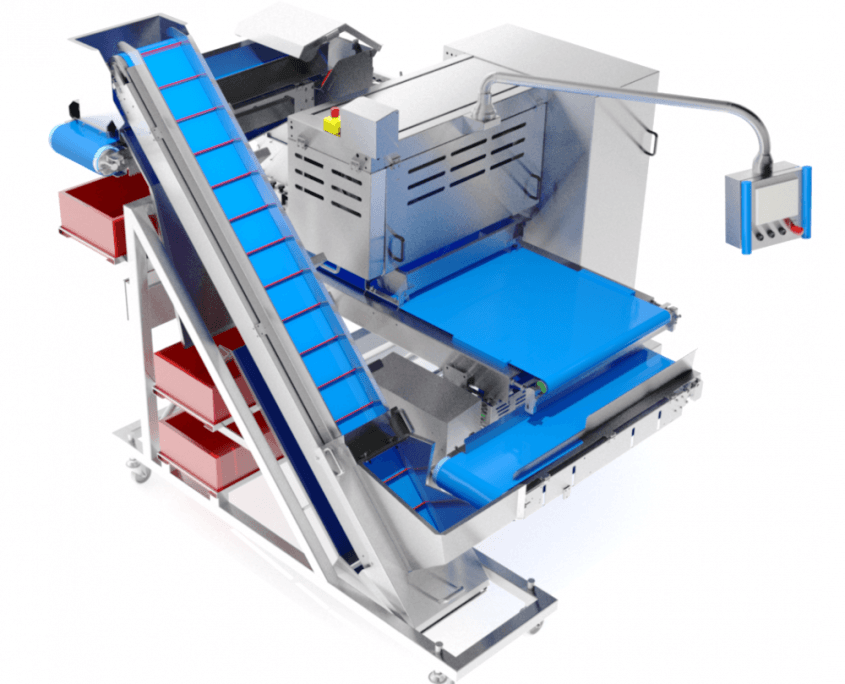

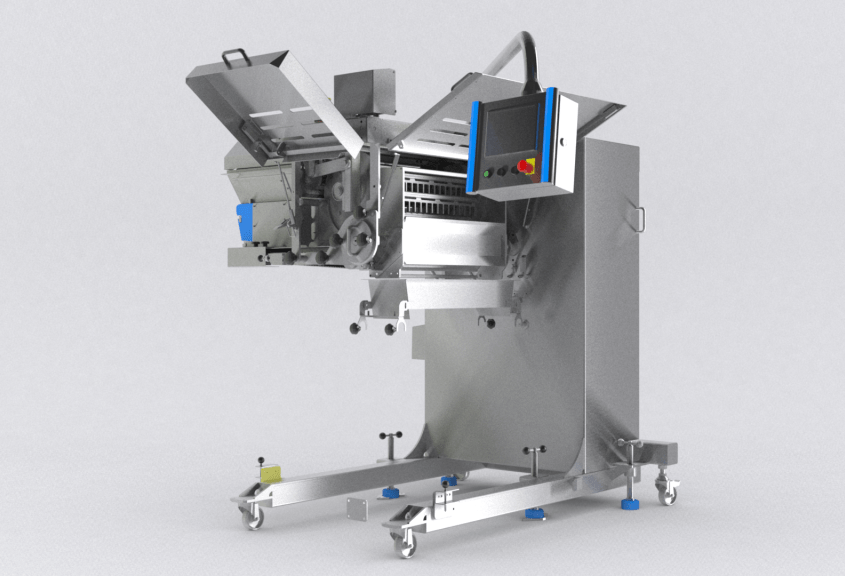

Decoration units

Universal applicator for:

- Grated cheese

- Vegetables

- Cubed meat or fish

- Walnuts and sliced almonds

- Raisins, etc.

- Almost all irregularly shaped spreading material

Configuration:

- Hopper

- Rotating rakes with lower belt

- Standard working width: 400 – 600 – 800 – 1.000 – 1.200 mm

- Mobile C-form frame construction stand alone

- Easy to clean with liquids because of the foldable and removable parts

- Constructed in stainless steel 304 as well as high-grade and food-grade plastics

- Optional: product conveyor / recovery system / target strewer

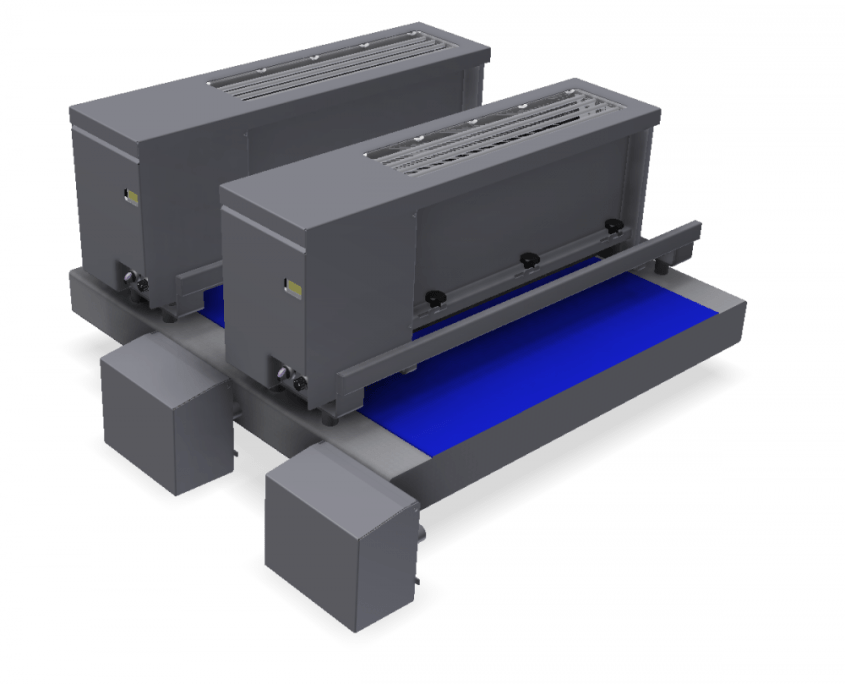

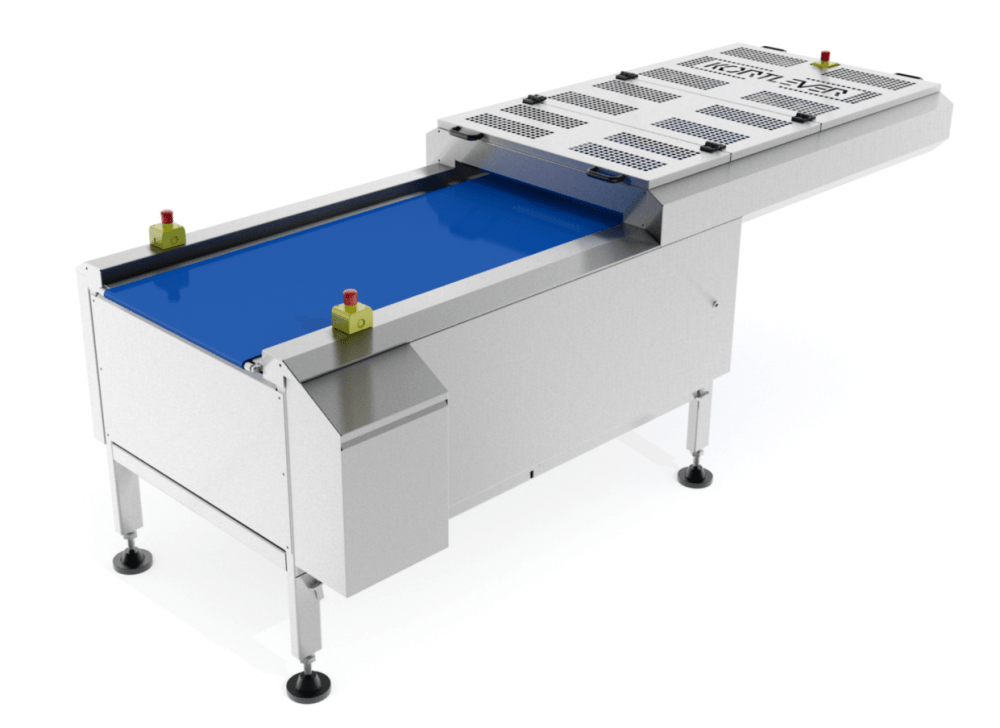

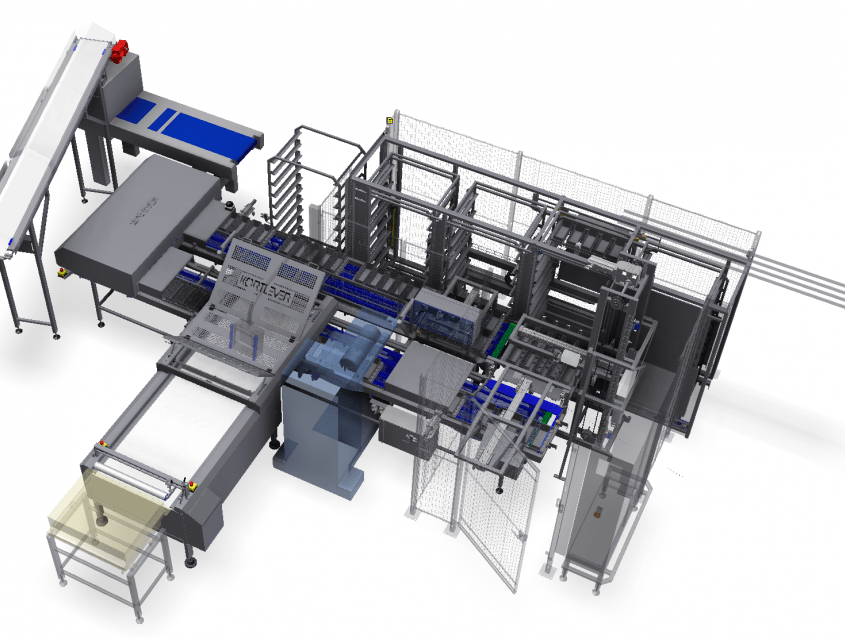

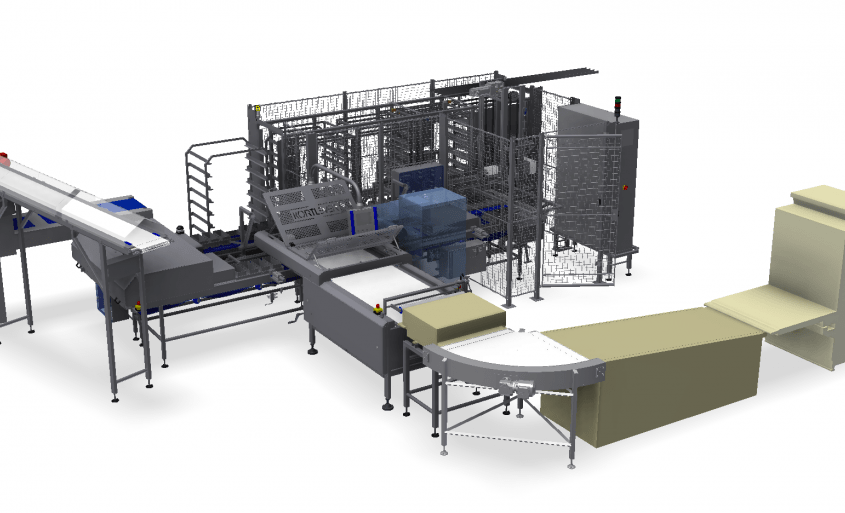

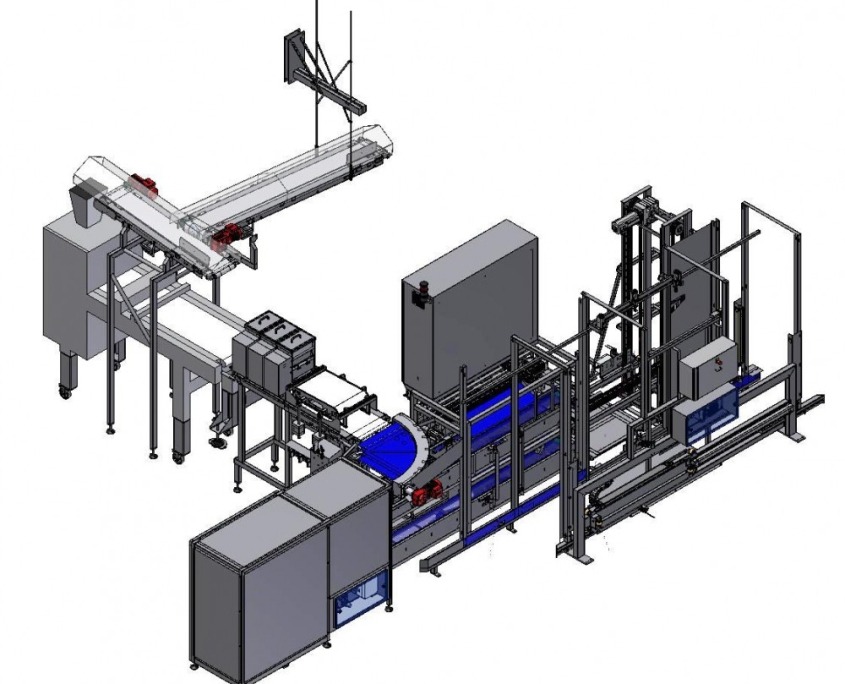

Panning systems

Panning systems for loading of trays, peel boards as well as proofing belts, ovens and frying oven.

- Panning lengths: 1.000 – 1.200 – 2.000 – 3.000 – 3.600 mm

- Working widths: 400 – 600 – 800 – 1.000 – 1.200 – 1.500 mm, as a special up to 3.600 mm

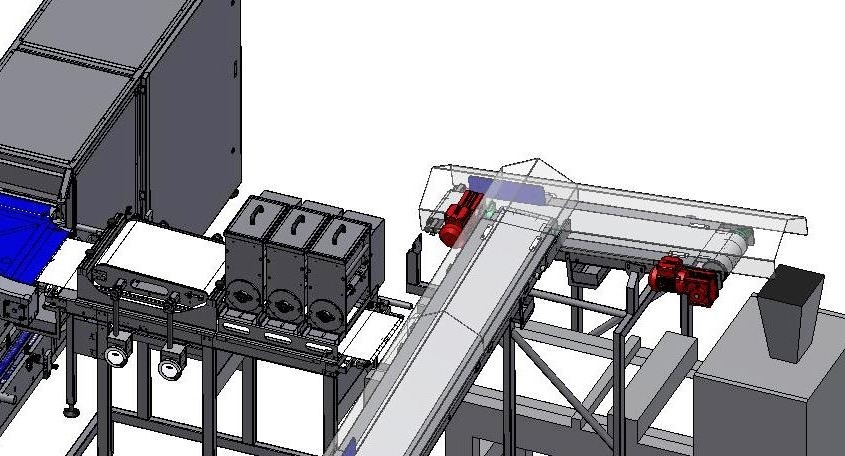

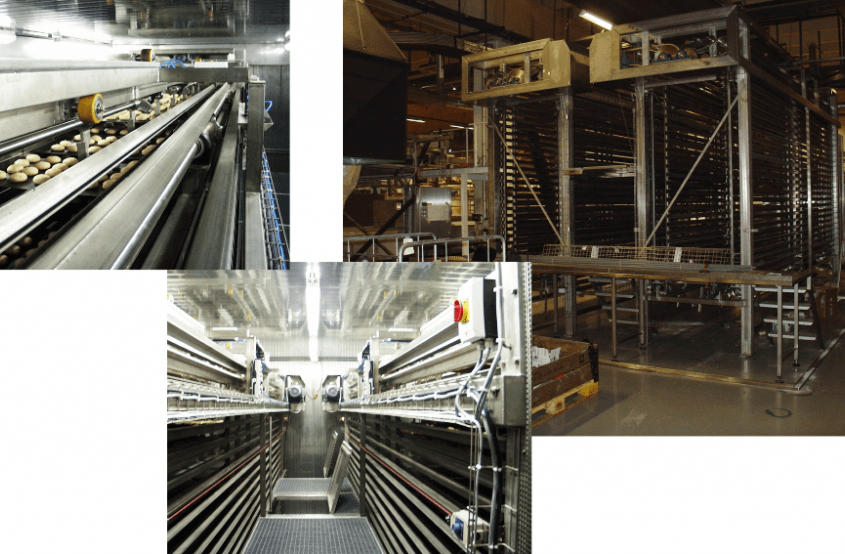

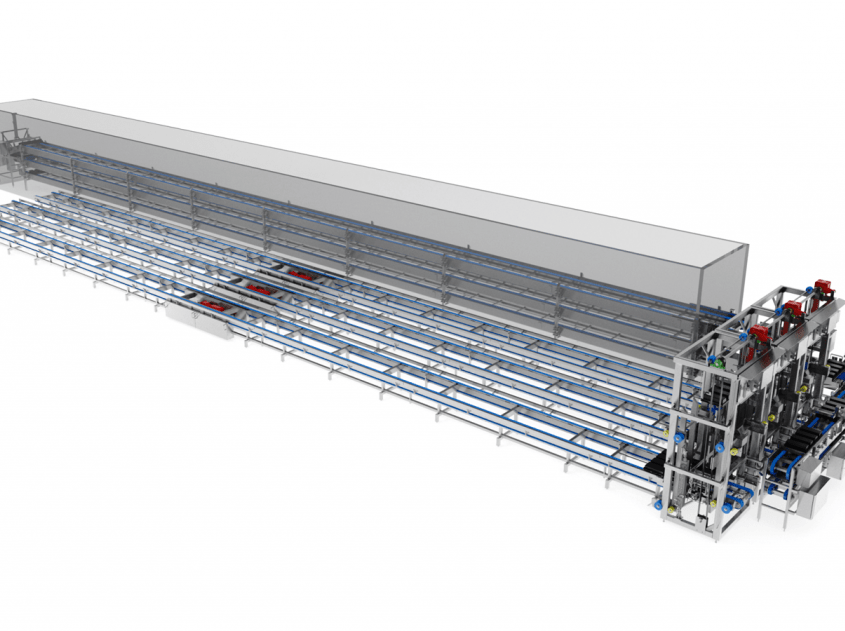

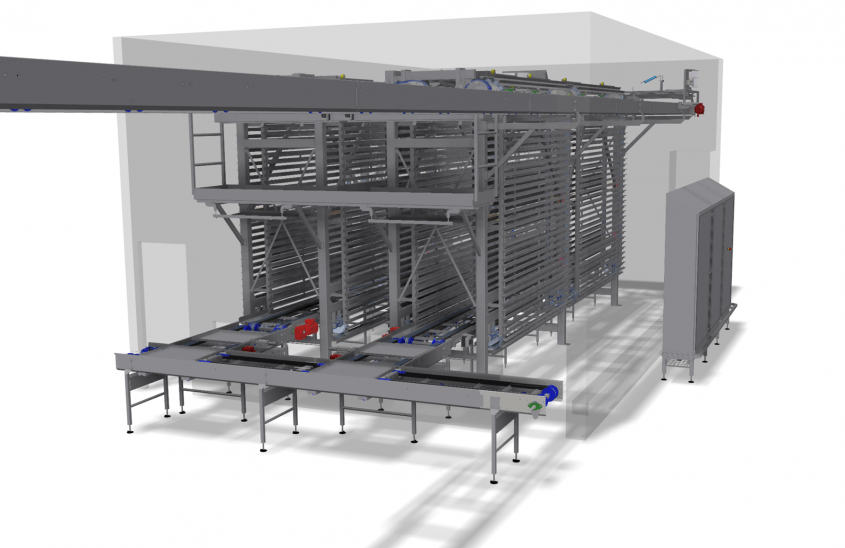

Paternoster final proofing installation for tin bread straps, baking trays and peel boards.

- Paternoster inline buffer system for tin bread straps, baking trays and peel boards.

- Paternoster cooling installation for trays.

- Paternoster inline buffer system for tin bread straps, baking trays and peel boards.

Capacity: on request

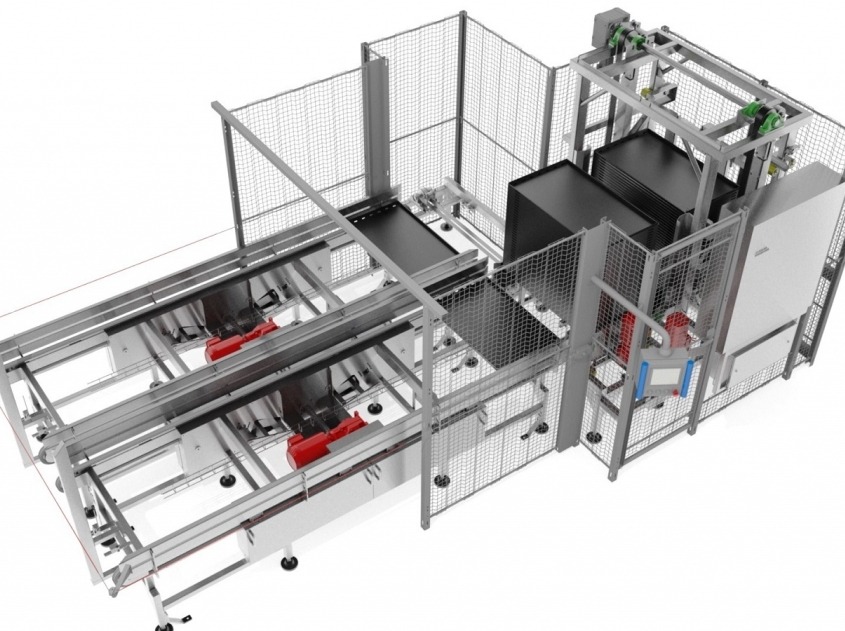

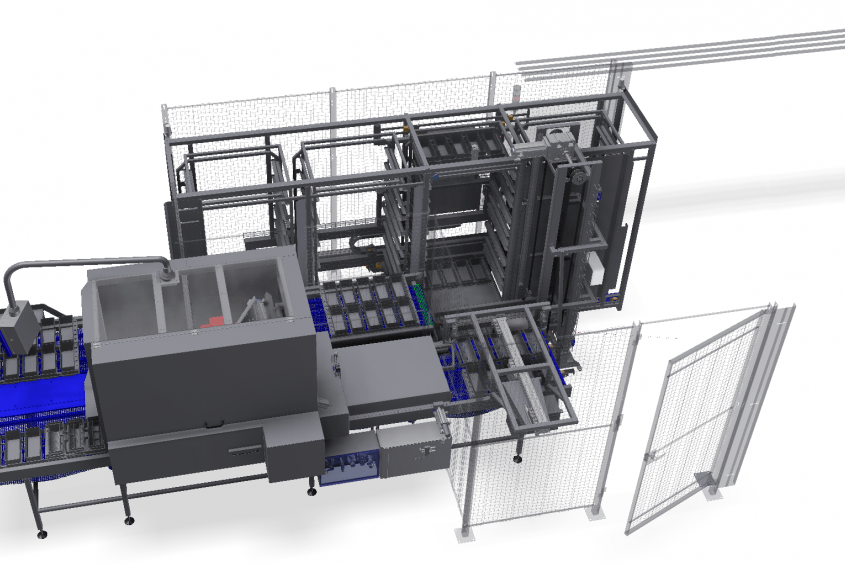

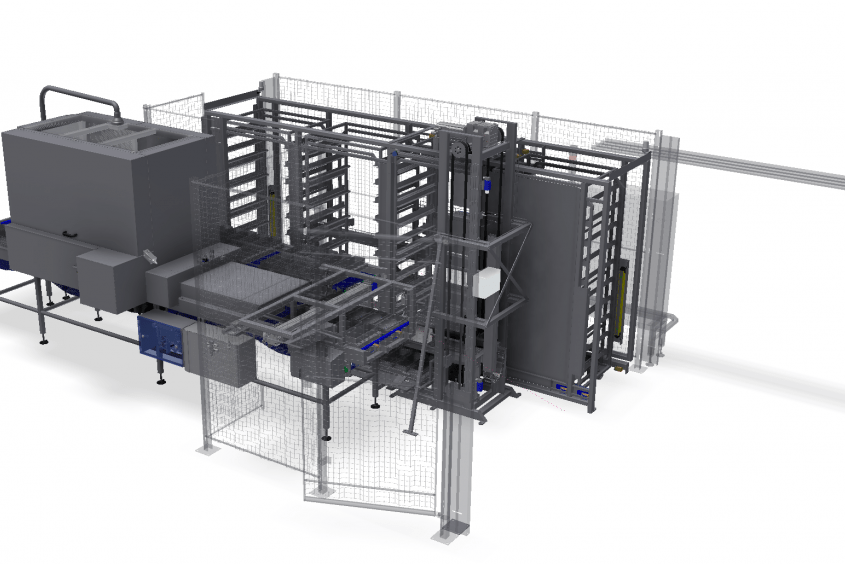

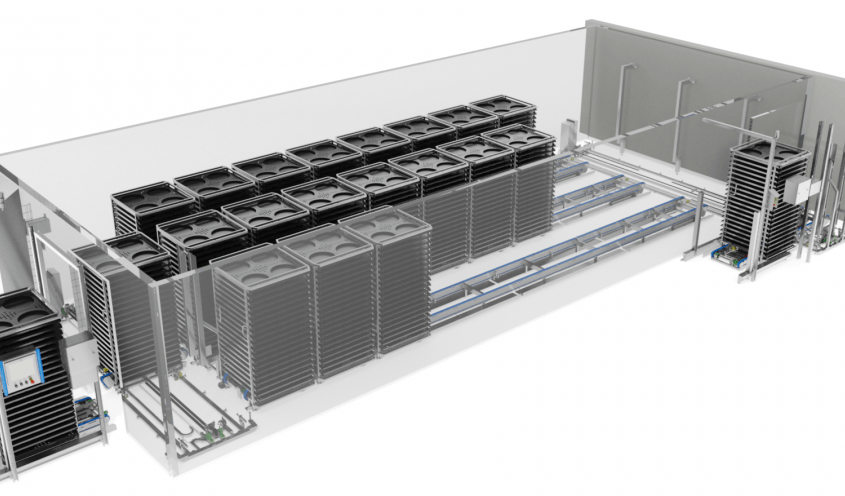

Rackhandling

- Automatic loading and unloading of racks with trays.

Capacity: up to 20 dough racks/1.000 trays/hr. - Proofing systems for racks, with automatic rack infeed, isolated housing and air conditioning.

Capacity: up to 20 dough racks/1.000 trays/hr. - Steam system for racks with automatic rack infeed, with isolated housing.

- Air conditioning for racks with automatic rack infeed, with isolated housing.

Cooling by means of air circulation with air in- and outfeed.

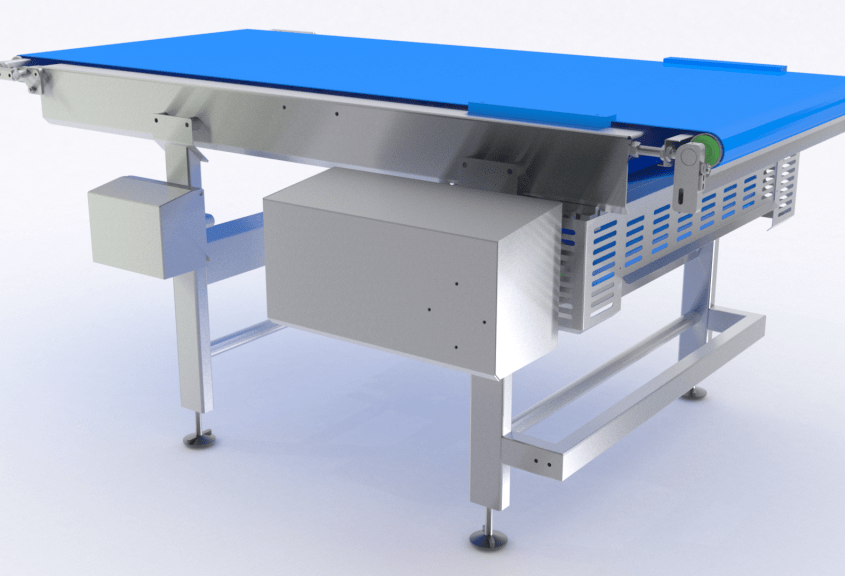

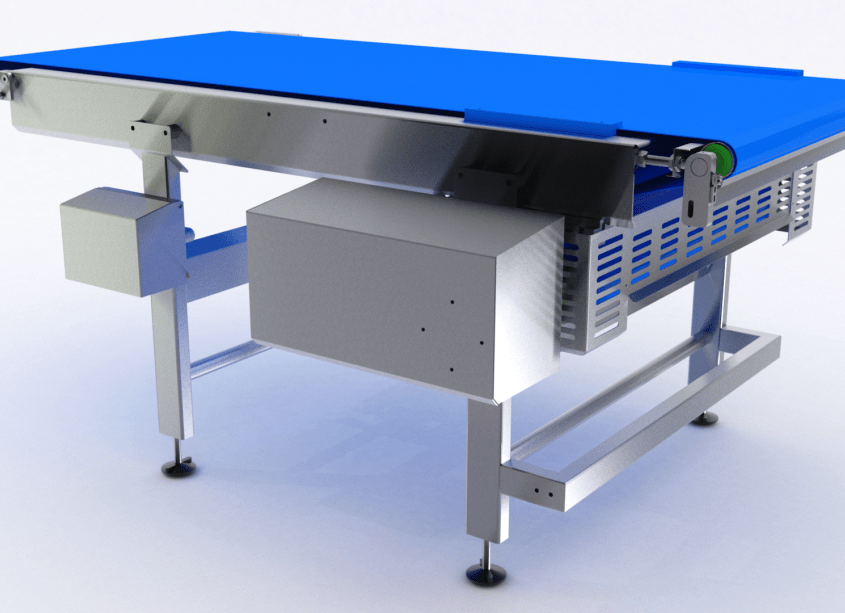

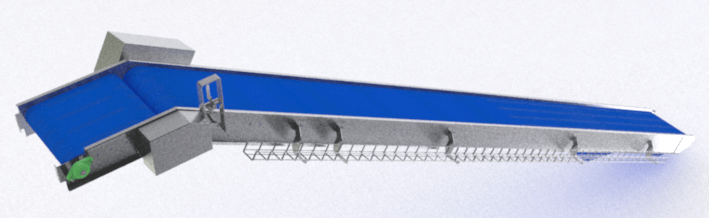

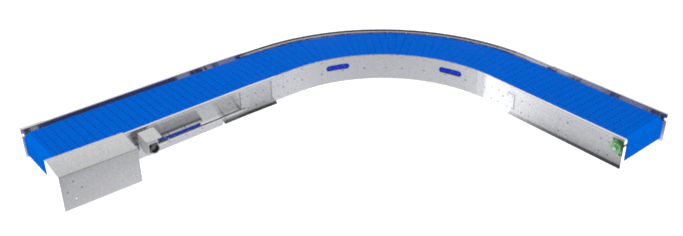

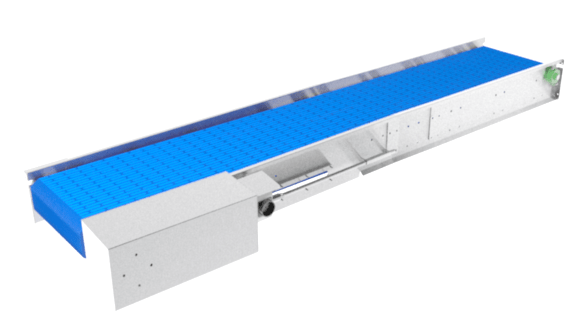

Universal conveyor systems

For any application. Transport from A to B or from advanced, dynamic buffer systems for product cooling in combination with linear loading or lift loading.

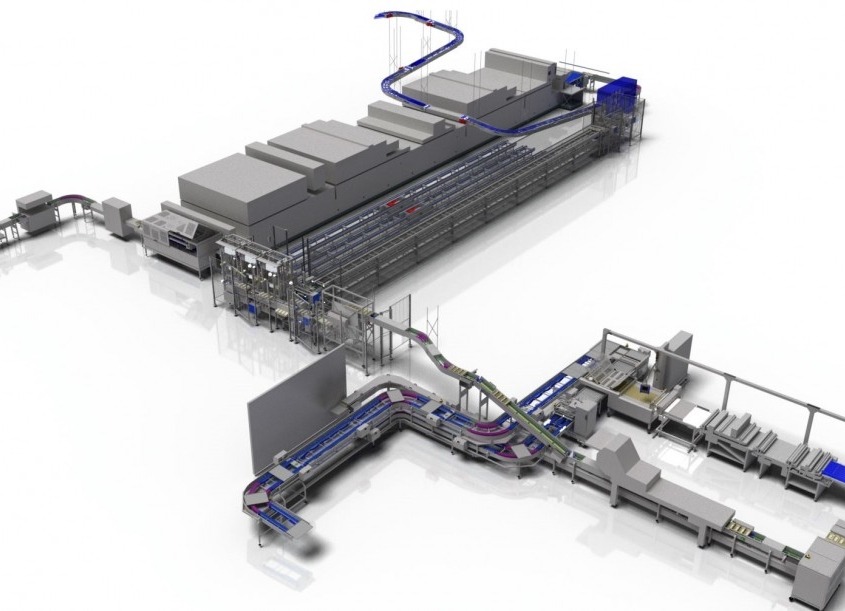

Complete bakery set-up

For the production of:

- Bread

- Bun rolls

- Special bread

- Dough related snacks

Project based planning and implementation of your and our concept realised with experienced project managers.

Contact information

- Energieweg 33 & 10

- 4231 DJ Meerkerk

- The Netherlands

- +31183352955

- info@kortlever.nl

- service@kortlever.nl

Welkom bij